Details

Features of ULF Coating

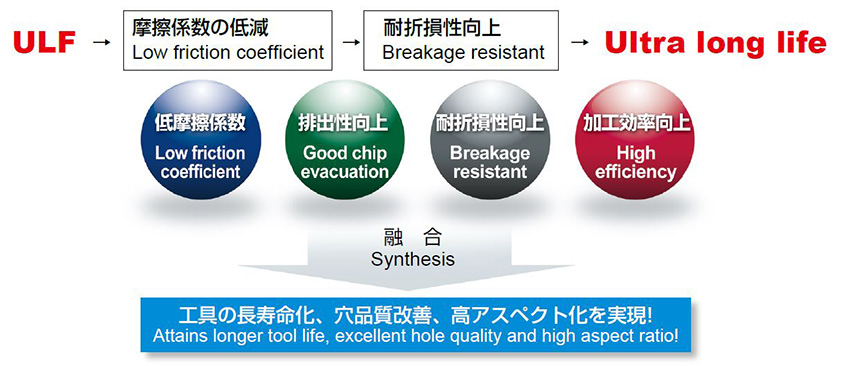

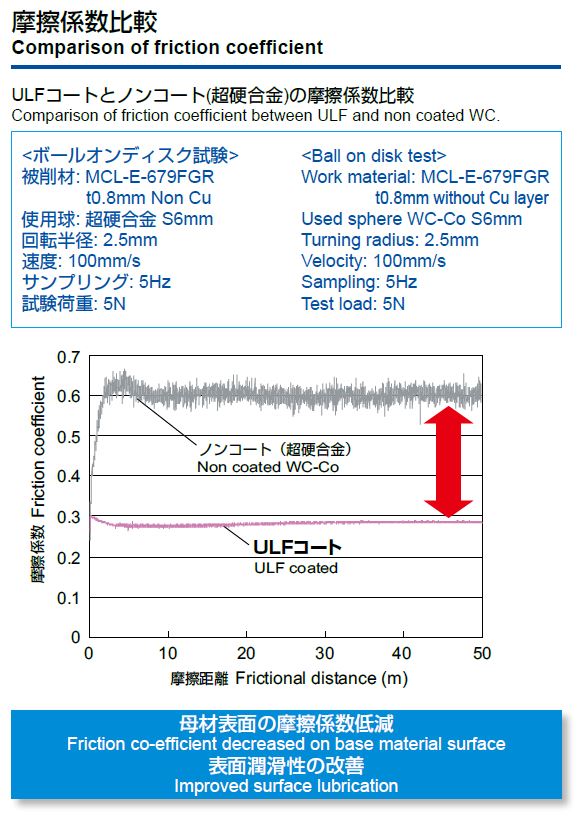

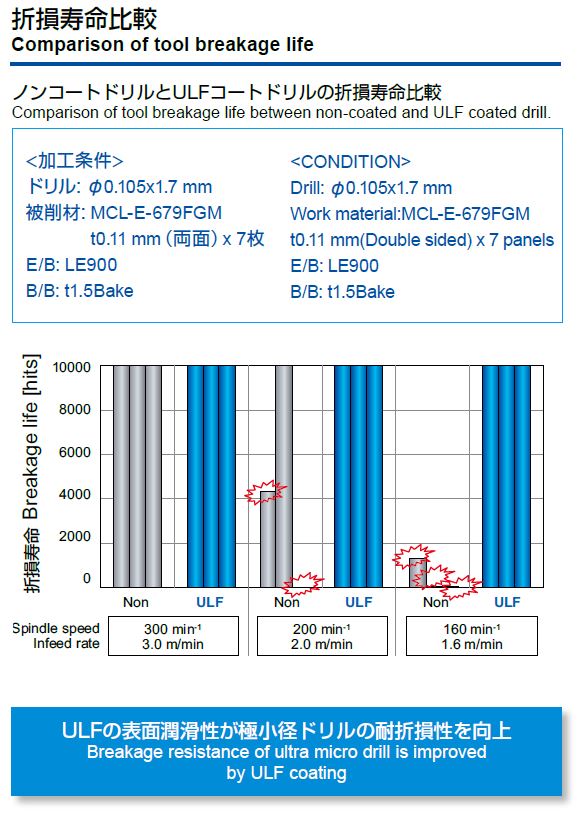

ULF (Uniontool Lubricant Film) coating features low friction coefficient.

We will develop drill bit geometry considering with the characteristic of ULF to meet further long life and stack up requests.

Technical data

ULF coated router RPEMU

RP20(Conventional)

RPEM(New)

*This is a picture of Non-coated routers.

FR-4 Spot facing

|

Work |

R-1566 t1.6mm x 1panel/stack(Halogen free, No copper) |

|---|---|

|

Conditions |

N = 25krpm, Fxy = 0.8m/min, Pocket depth = 0.5mm |

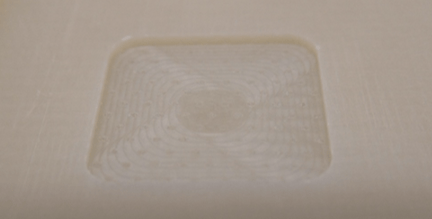

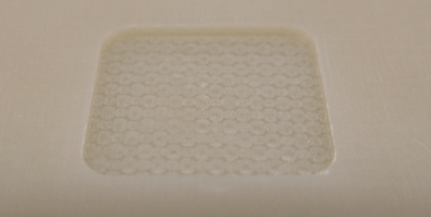

φ3.0 Non-coated(after 2m)

Conventional

RPEM

Due to optimized cutting edges of RPEM, cutting-mark on bottom surface will be controlled.

Copper Spot facing

|

Work |

C1020P t1.0mm x 1panel/stack |

|---|---|

|

Conditions |

N = 35krpm, Fxy = 0.4m/min, Pocket depth = 0.5mm |

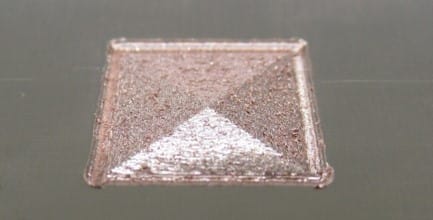

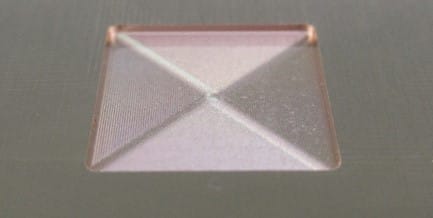

φ1.0 ULF coated(after 10m)

Conventional

RPEM

With ULF coated RPEM, less burr and smoother surface can be possible.

View more about ULF Coating on main site